ZhiDing Shelf--Small Detail, Big Impact

1.Material Selection for Shelves

We choose cold rolled steel of being product in China as ZhiDing main material-cold rolled steel has high utilization rate and can be used to make adjustable steel shelving of uprights, angle plates, beams, diagonal braces, etc. Cold rolled steel has higher hardness and very smooth surface, is not easy to deform, ensuring the stability and load capacity of racks. The surface can be powder coated or galvanized to improve corrosion resistance.

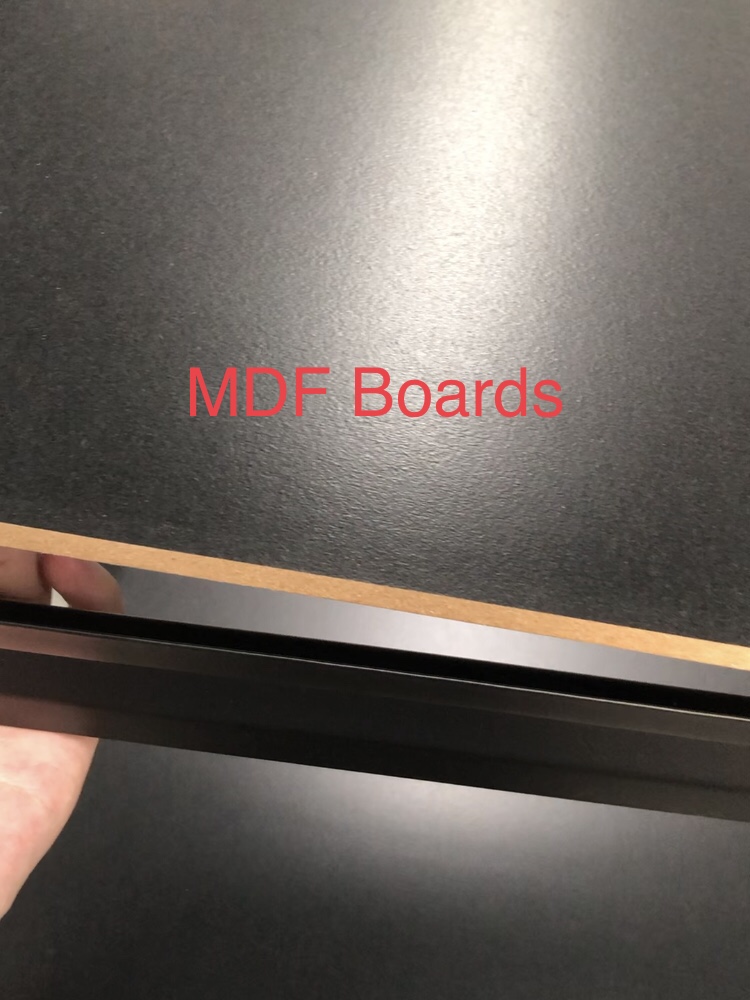

We choose MDF boards as our material. The tailor boards are waterproof and corrosion-resistant, and choosing edge banding will provide better results.

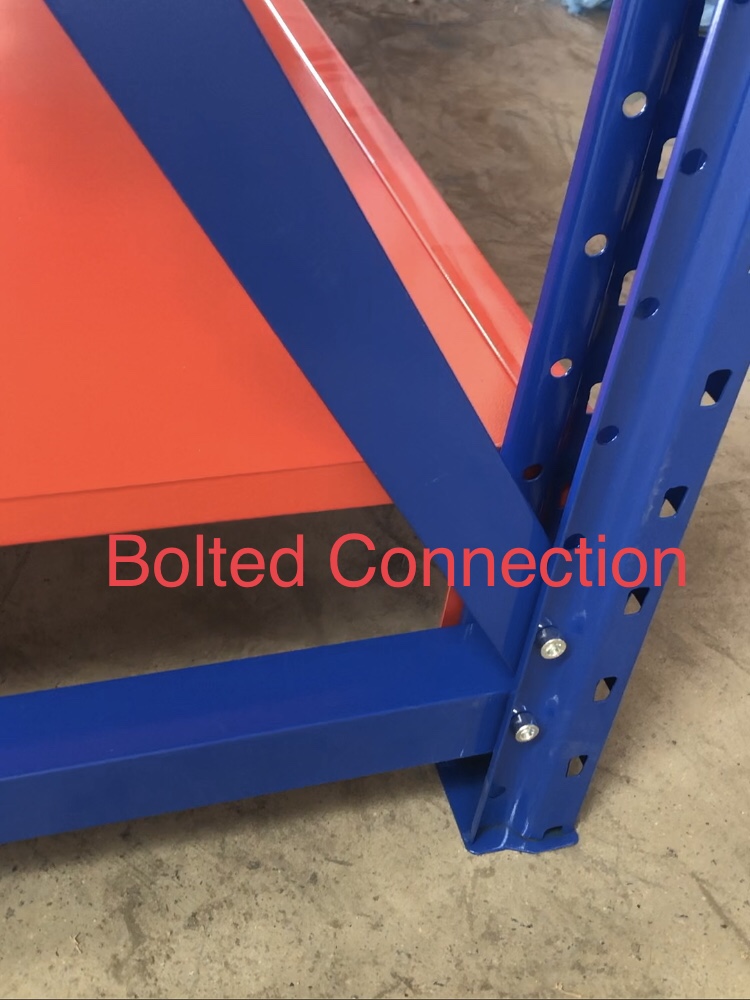

2.Shelf Linking Method

First is bolted connection, which is one of the most secure fastening solutions, serving as a crucial safeguard to ensure the safe and stable operation of medium duty rack. Shelves using this connection method offer easier and more flexible installation, with detachable and adjustable features.

Next is welded fixation. Welded fixation integrates the gaps and materials into one solid piece, providing greater load-bearing capacity, making it ideal for medium duty racking. This method simplifies the structure by eliminating connectors effectively reducing the risk of loosening.

Third is riveted fixation, which achieves high strength bonding through physical compression, belonging to cold working connection methods with excellent stability. Riveted racks offer both beauty and safety, making them currently one of the most popular shelving options.

3.Shelving Installation and Usage Guidelines

During installation, select level ground and verify all rack components are complete. Assemble strictly according to the instruction manual, and whenever possible, secure the racks to walls to prevent tipping.

Perform regular maintenance by checking for loose screws, deformed shelves, and cracked welds. Distribute the goods evenly.

Precision in details defines excellence–choose ZhiDing shelving, choose reliability!